charpy impact test fracture surface|charpy impact test fracture : factories Charpy impact testing (CIT) is an ASTM standard fracture mechanics technique used to. moderately high strain r. standard E231, requiring a 55x10x10 mm beam with a 45°, 2 mm . WEBFreeConvert supports 500+ file formats. Simply upload your files and convert them to M4A format. Alternatively, you can upload M4A files and convert them to a different format. All .

{plog:ftitle_list}

17 de jul. de 2023 · Os jogos de criptomoedas da Bets.io são seguros e confiáveis, e os jogadores podem jogar com confiança sabendo que seus fundos estão seguros. A .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

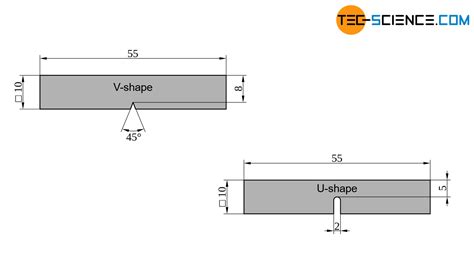

Charpy impact testing (CIT) is an ASTM standard fracture mechanics technique used to. moderately high strain r. standard E231, requiring a 55x10x10 mm beam with a 45°, 2 mm .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with jagged edges or shear lips, then the fracture was ductile. Usually, a material does not break in just one way or the other and thus comparing the jagged to flat surface areas of the fracture will give an estimate of the percentage of ductile and brittle fracture. The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .

The widely used Charpy impact test is a standard way to assess toughness quantitatively in notched specimens. In this test a standard bar specimen, with a square cross section and a V . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . When the .

The fracture surface of the Charpy impact specimen tempered at 240 °C, (a) macroscopic fracture surface; (b) crack initiation zone; (c) crack propagation zone; (d) shear fracture zone. . Fracture toughness-Charpy impact test-rockwell hardness regression based model for 51CrV4 spring steel. Mater Sci Tech, 30 (2013), pp. 1500-1505. Google .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

Despite the large use of the Charpy impact test, it is fracture toughness that is used for structural integrity calculations. . test temperature increases, the ductile crack extension increases, and the absorbed energy as well. By examining the fracture surface of the Charpy specimens, the ductile crack extension can be identified and measured.Fig. 3 reveals the SEM images of the specimen after Charpy impact testing. It is seen in Fig. 3(a) that the macroscopic fracture surface can be separated into shear and flat fracture zone, and the . Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar . Figure 8 — Charpy vs Impact test Fracture modes. . Its fracture surface has performed a high extensive plastic deformation and it has a very cracked surface with cavities. This is a very .

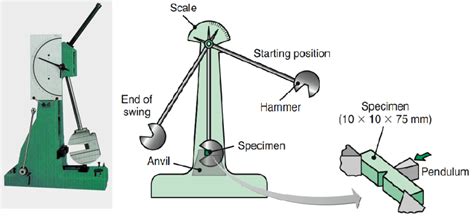

Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation of . portion of the fracture surface and the original (undeformed) cross section of the specimen (fig. 3, right).fracture surface changes from crystalline (no distortion) to brous or silky (major distortion at the sides). This shows that there is strong correlation between the energy absorbed and the portion of fracture surface undergoing distortion. The impact load can be applied in many di erent ways. In the Charpy test, the specimen has a The Charpy impact specimens were cooled down by an ethanol-dry ice (solid carbon-dioxide) bath kept at the test temperature. In order to establish the repeatability of the test results, experiments were conducted at least three times for each sample. Figure 9 shows the Charpy impact specimens after fracture testing.A typical impact testing machine is shown in Figure. 1. . causing an initiation of fracture from the notch. Figure 2 Charpy Test Specimen under Load. The most commonly used specimen, the Charpy V-notch (CVN), is 10 × 10 × 55 mm and has a V-notch 2 mm deep with a 0.25 mm tip radius. . The notch is placed perpendicular to the plate surface .

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of . In total, 26 pieces of standard Charpy notched samples were tested on a notched bar impact test machine. The fracture energy KV (J) . Only a single origin on the fracture surface of the Charpy impact CVN specimens was discovered on each specimen in the vicinity of the actual ductile crack front (see Table 1).

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D . Comparison of the experimental fracture surface on the SENT test with the simulated fracture surface. 3.3. Numerical prediction of Charpy energy at upper shelf temperature (0°C) . FE mesh for simulating the Charpy impact test with the minimum element size of L e = 0.1 mm, (b) . A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . for which the . A: The Charpy impact test was developed around 1900 and became known as the Charpy test after its inventor, Georges Charpy. It has since become a standard test method for evaluating material toughness. Q: What types of fractures can the Charpy impact tester evaluate? A: The Charpy impact test can evaluate both ductile and brittle fractures.

A JOEL 6500F field emission (FE) SEM was used to examine the fracture surface of the Charpy impact test specimens. Specimens for SEM examinations of fracture surface were saw-cut from. fractured test specimens, about 5 mm below the .

charpy impact testing definition

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.Charpy Impact Test. Full Code MET0102215. Module Type. E-learning. Description . - Explain an Introduction to Charpy testing, fracture surface appearance, and the history of brittle fractures; - Interpret the effects of a notch, and typical Charpy test results;

The impact energy absorbed during the Charpy impact test is related with the extent of plastic deformation and subsequent fracture initiation and propagation paths. During Charpy impact testing, tensile stress occurs at the notch-tip area of the Charpy specimen, while compressive stress occurs in the hammer-impacted area opposite the notch. The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test . The most common mechanical test to evaluate the fracture resistance of a structural metal is the Charpy-V impact test. Nearly all structural integrity assessment procedures use it.

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

energy and fracture surface features of API X65 steel plates using Charpy impact tests. For this purpose, 24 specimens were made with 8 different notch depths (3 specimens per notchA 4 K Charpy test is defined as a Charpy test in which the initial temperature of a specimen is 4 K. . EFFECT OF PLATE THICKNESS ON BRITTLE FRACTURE INITIATION FROM SURFACE NOTCH IN WELD FUSION LINE AND CORRELATION BETWEEN THE RESULTS OF LARGE SCALE TEST AND THOSE OF CHARPY TEST, Journal of the Society of Naval Architecture .

karl fischer volumetric titration procedure distribute

WEBEnjoy the thrill of online gaming with PGBET, the leading platform for sports betting, casino games, and more. Join now and claim your welcome bonus.

charpy impact test fracture surface|charpy impact test fracture